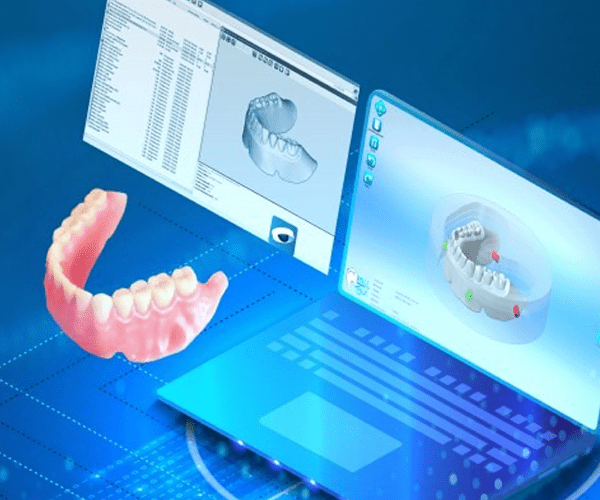

Dental CAD/CAM software

For milling centers and dental labs

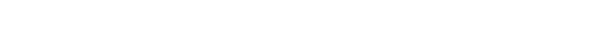

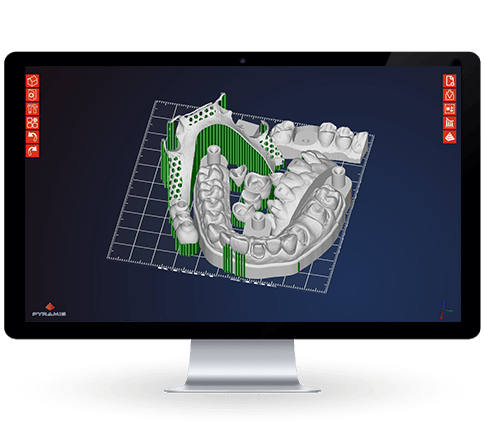

Innovative and easy to use CAD/CAM software

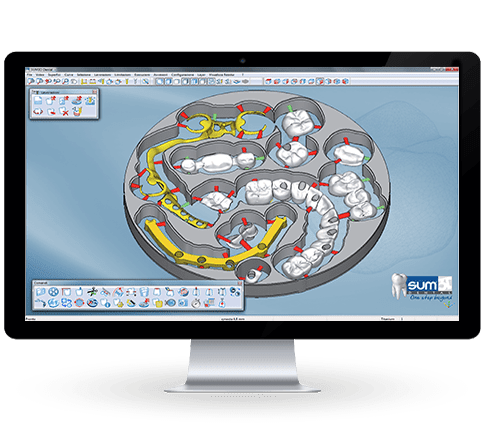

CIMsystem develops and supplies CAD/CAM software for dental manufacturing, creating technological and innovative products able to increase the quality and the efficiency of dental labs, dental clinics and milling centers.

Our strengths

Expertise

More than 30 years of spent in the development of CAD/CAM software to support and optimise business manufacturing performance while delivering top-quality products.

Know-How

An international team of experts supports our customers throughout all the phases of our solutions usage, from the preliminary consultancy to installation support and post-selling training. In your daily work our Team is next to you.

Flexibility

All our solutions are highly customisable, to meet the needs of our customers, today and tomorrow.

Our solutions

Do you have any questions? Are you interested in our products?

We are here to listen to you!

Events —

Events —

CIOSP - January 24/27 2024 - Sao Paulo, Brazil

24/01/2024 São Paulo, Brazil

CIMsystem will exhibit at CIOSP 2024, from January 24/27, in São Paulo, Brazil. Come to visit us at [...]

CADEX - October 18/20 2023 - Almaty, Kazakhstan

18/10/2023 Almaty, Kazakhstan

CIMsystem will exhibit at CADEX 2023, from October 18/20, in Almaty, Kazakistan. Come to visit us at [...]

ADX - March 30/April 1 2023 - Melbourne, Australia

30/03/2023 Melbourne, Australia

CIMsystem will exhibit at ADX 2023, March 30/April 1, in Melbourne, Australia. Come to visit us at [...]

News —

News —

CIMsystem Asia & Pacific celebration event: the evolution of a Company

28/10/2023

At the end of October (26-27), CIMsystem Company had the pleasure of gathering the most relevant bus [...]

CIMsystem USA Partners with Level UP CAD/CAM to Provide Training for MillBox in North America

10/07/2023

CIMsystem USA is excited to announce a partnership with Level UP CAD/CAM. As the official provider f [...]

Case Study Yndetech & CIMsystem: Milling and Laser Melting work together in the digital workflow

04/07/2023

When we talk about innovation in the dental field, we also talk about digitization of manufacturing [...]